Microplater Classic

Instruction manual for Microplater Classic

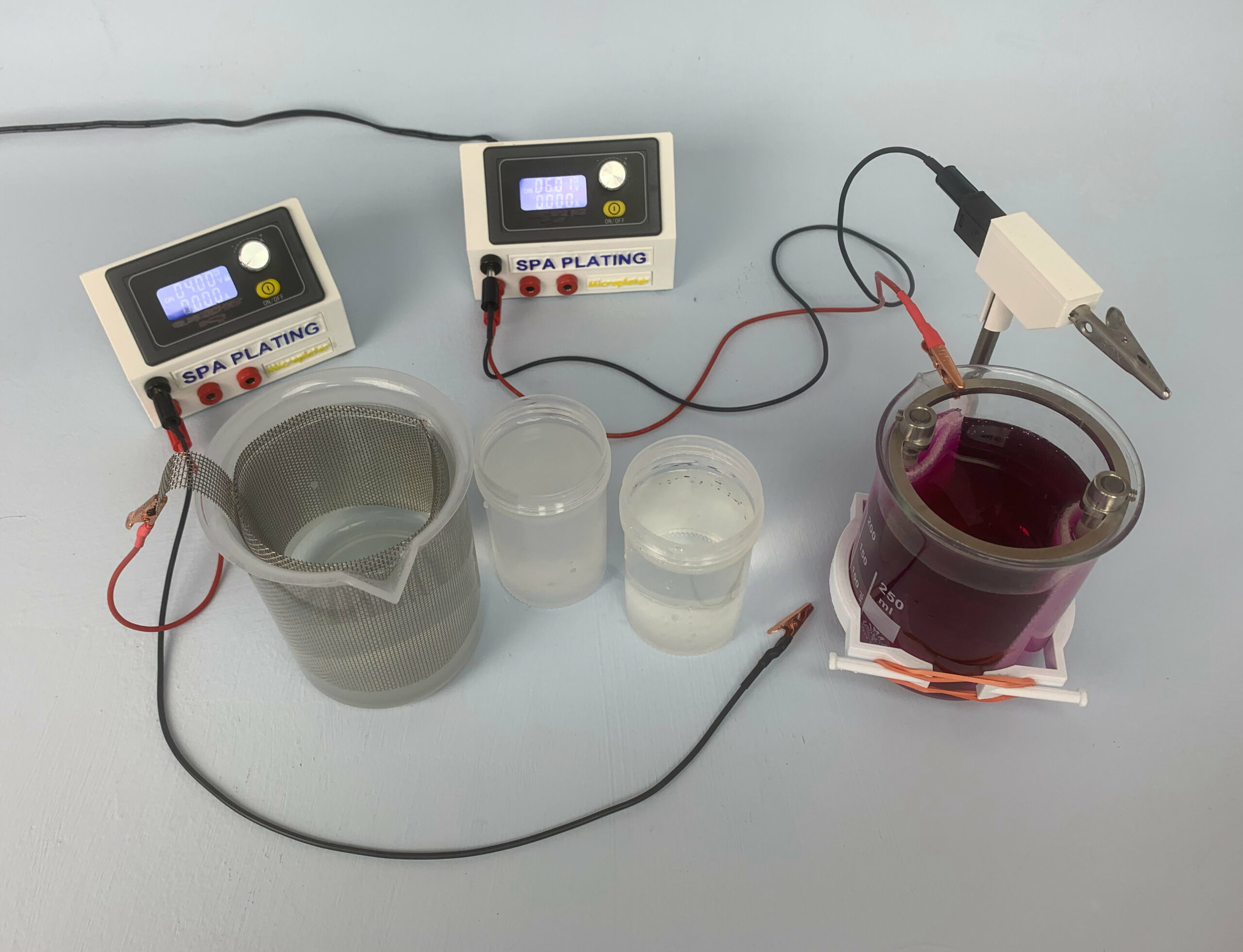

You can use the Microplater Classic for pen, brush and beaker/tank electroplating

It is particularly useful for tank plating as you can programme it.

You can also monitor the amount of electricity you are using (in amp hours) and this, when used with our online calculators, helps you plate to specific thicknesses.

The default settings do not need to be changed but can be viewed. This is talked about below.

Overview

The Microplater Classic is an electroplating rectifier which outputs dc voltage within the range 0.6 – 30 volts and amps between 0.00 and 3.5

You can set the volts and amps (along with other parameters) using the dial. To control the output, use the yellow on/off switch.

The black negative output and three red positive outputs allow for the three different processes of pen, brush and tank plating to be run from the Microplater.

There is plenty of venting on the sides and base of the unit.

Switching on

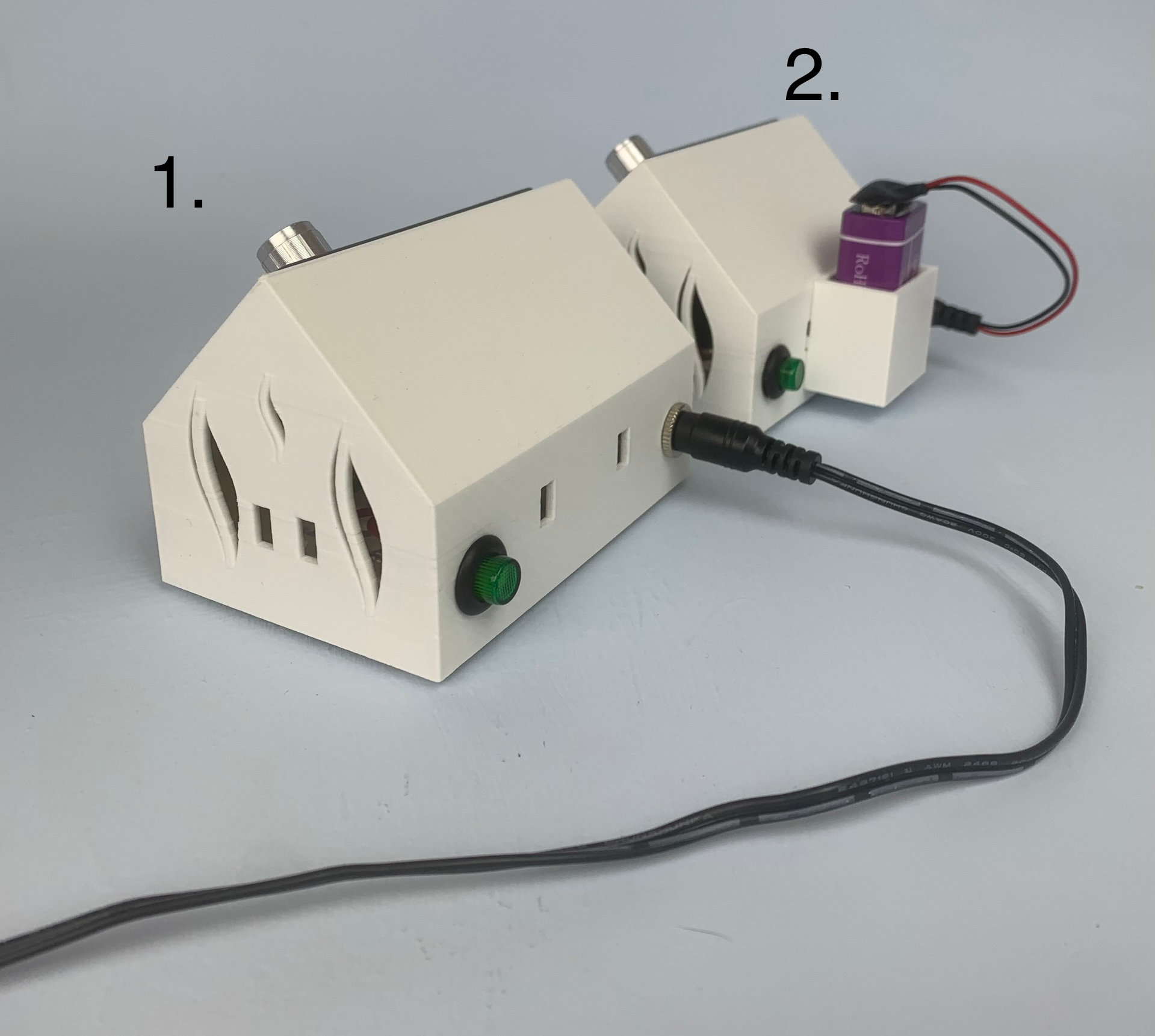

To power up the unit, plug in the power lead from the adapter or 9 volt battery into the socket on the back of the unit and press the green button. This will light up when the power is on.

Please note that we only recommend using the battery option with pen plating, not with brush or tank.

The Microplater can be powered with a lead (1) or with a battery (2).

How to switch the Microplater Classic to pen and brush plating mode

1. Make sure the output indicator (1) displays ‘OFF’ by depressing the yellow Output On/Off switch (3).

Take a note of the correct voltage for your pen or brush plating solution – it is displayed on the side of your plating solution bottle.

2. To set the voltage, briefly depress the dial (2). The last digit in the output indicator will start flashing. You can now adjust this digit up or down by turning the dial clockwise (up) or anticlockwise (down).

To move to the next decimal place, depress the dial again and while this digit is flashing you can adjust this one, by turning the dial.

Continue to the next digit to complete the voltage setting.

3. Select the amps by pressing and holding down the dial until the last digit of the amps starts flashing. As above, adjust the amps by rotating the dial clockwise and anticlockwise. To set all the decimal places of the amps, follow the same procedure you followed for the volts.

4. For both pen and brush plating mode, adjust the amps to 3.5 Please note that 3.5 amps is very unlikely to be reached during the plating process and only indicates a maximum value.

The volts figure, however, should remain unchanged from its set value during the plating process.

6. When you’re ready to start plating, press the output ON/OFF button so that it says ‘On’ in the output indicator.

Please note that you can program the output to be permanently on in Program Mode which is discussed below.

How to switch the Microplater Classic to beaker/tank plating mode

Tank plating is different to pen or brush plating in that the important setting is the amps rather than the volts. To work out the correct amp setting for your piece of work and the tank plating solution you’re using you will need to use one of our online plating calculators. Links to these can be found under ‘Calculators’ on our main menu. Once you have established the correct amp setting, take a note of this.

1. Make sure the output indicator (1) displays ‘OFF’ by depressing the yellow Output On/Off switch (3).

2. First set the volts to 5. This will be the same for every subsequent tank plating job you carry out and is the standard volt setting for tank plating. Follow the same procedure for selecting the correct volts as that outlined above for pen and brush plating.

3. Now you will need to enter in the amp setting you have worked out with one of our online calculators. Select the amps by pressing and holding down the dial (2) until the last digit of the amps starts flashing. As above, adjust the amps by rotating the dial clockwise (up) and anticlockwise (down). The amps figure should remain unchanged during the beaker/tank plating process.

4. Lower your work into the plating solution and press the yellow ON/OFF button to start plating.