This gold pen and brush plating kit has everything you need for top quality gold pen and small scale brush plating.

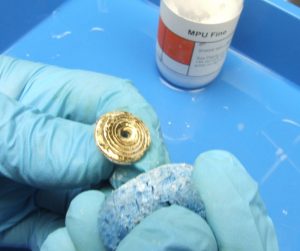

It includes the essentials such as our Gold Pen Plating Solution, our Nibs for Plating Pen and one of our unique surface preparation compounds, MPU Fine.

Our Gold Pen Plating Solution contains 12 grams of gold per litre and we have developed this solution in house with our own R&D team.

It is powered by our EasyPlater. This is Spa Plating’s in-house designed and manufactured power source for our pen and brush plating process.

You can buy this kit as it is or if you want, you can use it as a guide to put together your own bespoke kit. Click on the items in the kit list to the right to see detailed product information.

Our customers use this kit to gold plate items such as jewellery, electrical contacts and dental work.

You can use the full range of our pen plating solutions including precious and base metals with this kit – please click HERE to see a full list of our pen plating solutions. These plating solutions are not included in this kit – you would need to add these to your order.

Not suitable for plating on non-conductive surfaces.

For further products related to this gold pen plating kit, please see below in our “Related Products’ section.

A note on our kits;

Every item in our electroplating kits

- makes an important contribution to the overall success of the plating process

- has been thoroughly tested to ensure it performs its job at the highest level in the overall electroplating process

- is either made in-house or has been carefully sourced from our trusted suppliers

These factors ensure consistent, top quality plating results for a fair price.

Key Kit Contents

EasyPlater – unique to Spa Plating, and easy to use powersource designed and made in-house expressly for our pen and brush plating process.

1x Plating Pen Design and manufacture unique to Spa Plating with a removable and exchangeable electrode Gold silver and pen plating on a variety of small metal surfaces

MPU Fine No need for a separate activation – just give the surface of you work a thorough clean with MPU Fine and start plating Preparing the full range of metal surfaces for plating

Gold Pen Plating Solution 12 grams of gold per litre; concentrated formulation for efficient gold pen plating. Quickly building a hard wearing layer of 24 carat gold for decorative and functional applications. Good for selective gold plating of jewellery and PCBs

Silver Pen Plating Solution 75 grams of pure silver per litre; highly concentrated, so quickly builds a thick layer in excess of 5 microns, without having to continually replenish the pen Many applications such as covering fire stain and solder joints and plating electrical contacts

Fibre Nib x1, Fine Fibre Nib x1 Specially shaped to fit our pens to improve electrical contact and therefore, functionality. Can be used multiple times – just rinse well in running water when changing to a different plating solution. Rhodium pen plating claws on diamond set rings

Copper crocodile clip Jaws made of pure copper Makes excellent electrical contact and reduces the risk of scratching on highly polished surfaces

Our Easy Plater is designed specifically for the Spa Plating pen and brush plating process. It has a voltage range of 1 - 8.6 and is very easy to adjust, with a clear voltage readout. It comes with its own 12v adapter.

1. Connecting up the EasyPlater

Insert the adapter plug into the socket on the back of the EasyPlater. Plug the adapter’s three pin plug into the power supply. To turn the EasyPlater on, depress the green button on the back. This will glow green, showing that the EsyPlater is turned on.

2. Setting up the EasyPlater for pen plating.

Connect up the EasyPlater as shown in the picture, with one end of the red lead plugged into the red socket on the EasyPlater and the other end of the red lead into the port at the end of you plating pen.

Plug in one end of the black lead into the black port of the EasyPlater and attach the crocodile clip to the other end of the black lead.

All of these items are included in our Gold Pen and Brush Plating Kit.

Once you have connected up the red and black leads, you are now ready to start pen plating. Before you start you will need to enter in the correct voltage level for the pen plating solution you are using. You can find this information of the side of your bottle of Spa Plating pen plating solution. Set the volts on your EasyPlater by turning the big silver knob until the correct voltage appears in the LED readout.

Please watch the video to see detailed instructions.

3. Setting up your EasyPlater for brush plating.

Follow the steps above for connecting up the red and black leads. You can use our plating pens with a short electrode fitted for brush plating. This is suitable for small scale brush plating, for example watch parts or items of jewellery.

If you want to use the EasyPlater for brush plating larger items, you can fit one our electrode handles with our electrodes developed for brush plating. This video shows how to gold brush plate on stainless steel with the EasyPlater.

General guide;

Certain small items, for example Swabs, Nibs and Plating Pens can be sent by normal post within the UK

- The courier option for UK deliveries is FedEx

- Free UK mainland delivery available on orders over £200

- International orders usually 3-5 working days.

For all price quotations for deliveries, please add your items to our shopping cart. You will be able to see the shipping costs by clicking on the ‘Calculate shipping’ button in the cart and before checking out.

You can access our MSDS by scanning the QR code which is on our product bottles.

Here is a video to show you how;

Plating Durability

‘Hard’ vs ‘Soft’ gold plating

Q

Hello, can you advise me re durability of plating types. I have a battery pen plater and it’s great for detail on jewellery and I apply to vermeil standard but another jeweller said pen plater plating is not as durable/is softer than tank plating. Can you confirm if this is the case so I know which direction to go with my new kit.

A

Thank you for your enquiry.

The type of plating solutions we sell are hardened but then saying that, they are still quite soft when compared to other metals like copper and brass.

For any given thickness, pen plating is just as durable as tank-plated gold. The important thing is the thickness. Thick deposits can be built up with both pen and brush plating, but it may take a lot longer depending on the surface area and shape of the article you are plating.

It is possible, using our online calculators, to estimate how long it would take to pen plate Vermeil gold (2.5 microns). Once you have established the surface area of your work piece and knowing the thickness (2.5 microns) it is possible to input these into the calculator and get an estimate of time plated.

I have just done this for a ring of surface area 8 square centimetres and the time to pen plate it to Vermeil standard is 95 minutes (just over one and a half hours), while the time to tank plating it is 22 minutes.

So if you’re going for Vermeil-standard work, it may be the best idea to look at out tank/beaker plating kits.

Kind regards

Richard Palmer BSc(Chem.) MRSC

Director