For export outside the UK and the EU only.

Please note: Requires further additions in order for it to function.

Please refer to the Tech Specs and Product Details for more information.

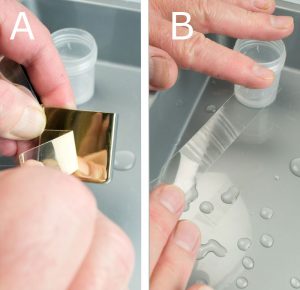

This plating solution can be used for both brush and tank plating very adhesive layers on to difficult-to plate metals such as chrome, surgical steel and dental alloys. When brush plating, all swabs can be used with this solution, however for longer life we recommend using S-Type Swabs which can be purchased by clicking on the link in the ‘Related Products’ section below this panel.

It is primarily used as an adhesive undercoat for other metals such as gold, silver, palladium and platinum and should not be plated to a thickness of over 0.1 micron.

Click the ‘Tech Specs’ tab for instructions on how to prepare 1 litre of Gold Strike Brush and Tank from the export only version.

Brush plating voltage: 3 – 4 volts

Plating Factor (tank): 0.03 amp/cm2 (see Tech Specs)

Gold content: 2 grams per litre

HS Code: 3824 99 70

For information on preparing the working solution, please click on the Tech Specs tab.

- Strike plate chromium, tungsten, dental alloys and more

- Recommended thickness: 0.1 micron

Operating Conditions and Deposit Data – Brush Plating

| Voltage |

3 – 4 volts |

| Temperature |

20 – 25 °C (see notes) |

| Gold Concentration |

2 g/l |

| Electrode |

Carbon or platinum |

| Gold content in plate |

99% – 99.5% |

| Plating Rate at (3 volts, Carbon Electrode, 20 °C) |

0.07 micron per minute (spot) |

| Plating Rate at (4 volts, Carbon Electrode, 20 °C) |

0.09 micron per minute (spot) |

| Recommended plating thickness |

0.1 micron |

| Coverage |

10ml will cover 80 cm2 to 0.1 micron |

| Hardness |

185 Hv |

| Density of deposit |

19.3 g/cm3 |

| Stress |

Not known |

| Special storage requirements |

Away from sunlight |

| Shelf life |

1 – 2 years |

| Health and Safety classification |

Harmful |

| Special considerations |

None |

| Transport (UN number) |

Not classified as dangerous goods |

Notes:

- The specifications above relate to the final mix with sulphuric acid added not to the as-shipped version.

- When plating in recesses, we recommend using the using the Plating Pen (8 – 10 volts, Fibre Nib).

- Plating rate decreases considerably below 20 °C

- We strongly advise against the use of stainless steel anodes for most of our plating processes

- Plating rates are calculated over a sample area which is permanently covered by swab.

Operating Conditions and Deposit Data – Tank Plating

| Plating Factor |

0.01 to 0.04 A/cm2 (recommended: 0.03 A/cm2) |

| Plating rate at 0.01 A/cm2 |

0.02 micron per minute (at 30°C) |

| Plating rate at 0.02 A/cm2 |

0.07 micron per minute (at 30°C) |

| Plating rate at 0.03 A/cm2 |

0.10 micron per minute (at 30°C) |

| Plating rate at 0.04 A/cm2 |

0.11 micron per minute (at 30°C) |

| Recommended plating thickness |

0.1 micron (about 1 minute process time) |

| Temperature |

18 – 35 °C |

| pH |

~ 1.0 |

| Gold concentration |

2 grams per litre |

| Agitation |

None |

| Electrode |

Mesh |

| Gold content in plate |

99.9% (balance carbon, nitrogen) |

| Cathode efficiency |

5% at Plating Factor = 0.03A/cm2 |

| Hardness |

190 – 210 Hv |

| Density of deposit |

19.3 g/cm3 |

| Stress |

Medium |

| Special storage requirements |

Away from sunlight |

| Shelf life |

1 – 2 years |

| Health and Safety classification |

Harmful |

| Special considerations |

None |

| Transport (UN number) |

Not classified as dangerous goods |

Notes:

- Plating rate and throwing power increase with temperature.

- For recessed items consider increasing the temperature up to 40 °C and Plating Factor up to 0.1 A/cm2

for one minute.

Gold Strike Export – Instructions for Customers

To prepare 1 litre

1. Add 800ml of Gold Strike Export to a 1 litre graduated beaker or measuring cylinder.

2. Add 110 millilitre of Battery Acid (35%). See notes below.

3. Make up to 1 litre with distilled or deionised water.

4. Add to plating beaker or store in original bottle.

Notes:

If 35% sulphuric acid is not available, please contact us with the percentage which

is available and we will advise on the addition accordingly.

Some items are regulated for transport and can only be delivered to destinations in the UK and countries within the EU. Alternative or substitute products are detailed in the ‘Description’ tab of this tabbed panel or under Related Items below this tabbed panel.

For all price quotations for deliveries, please add your items to our shopping cart. You will be able to see the shipping costs by clicking on the ‘Calculate shipping’ button in the cart and before checking out.