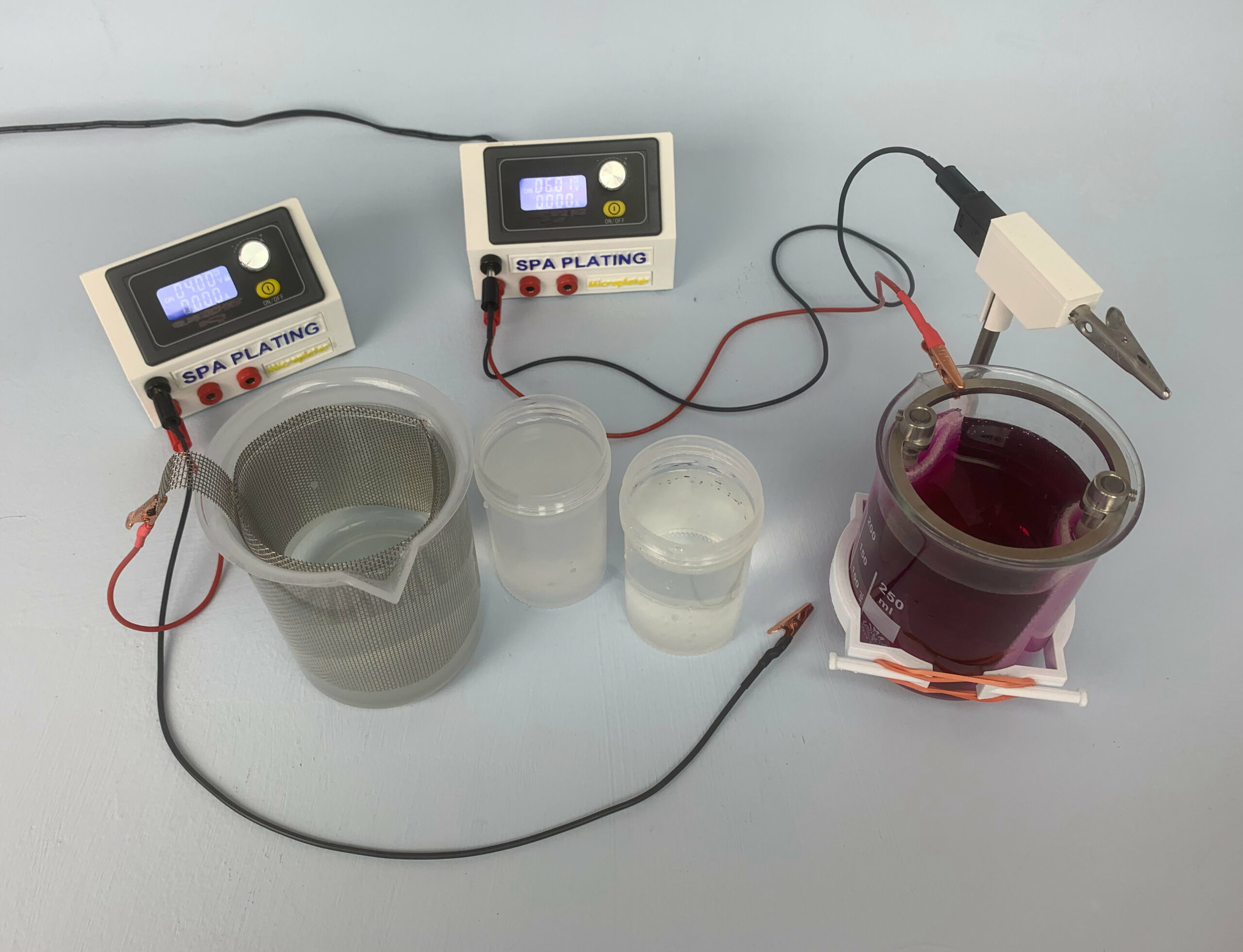

This cyanide free silver plating kit is ideal for bright silver layers of up to 10 microns thickness. The price of the kit includes 1 Litre of our Silver Tank Plating Solution HS. The advantages of this Silver Tank Plating Kit – HS process are:

– High speed silver plating

– Long life plating solution – silver replenished from electrodes.

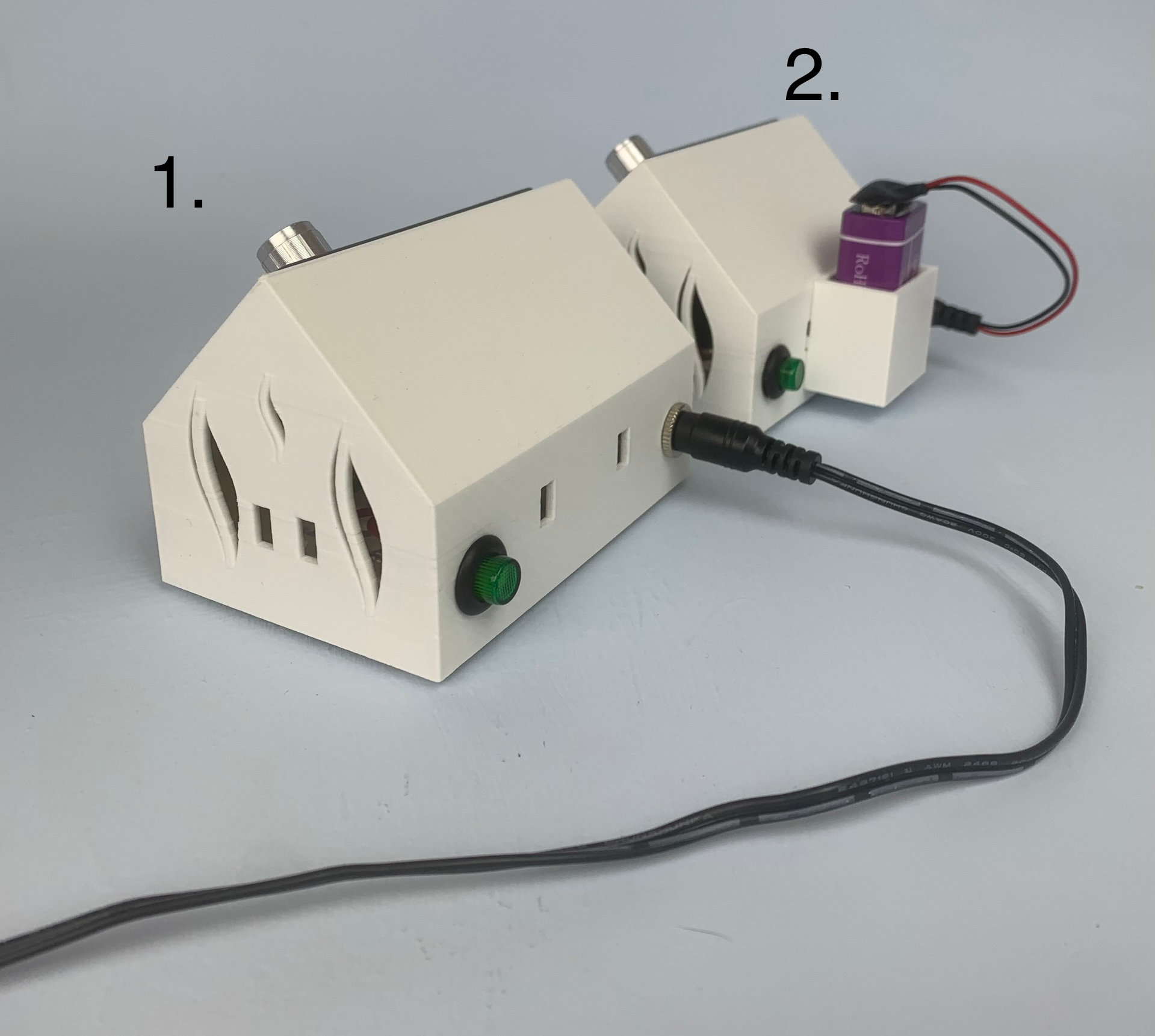

Scaling up or down; you can scale the volume of your kit up or down by swapping in different volumes of our plating beakers. You can also switch easily between our different plating solutions, as the Spa Plating tank plating process is very similar across all of our tanks plating solutions.

If you want to scale down the volume of the 1 litre kit to a 500ml kit for example, these are the core items you will need to change;

Silver Tank Plating Kit HS – 500ml

Silver Tank Plating Solution HS – 500ml

Beaker Ring for Plating in a Beaker – 500ml

Silver Rod Electrode for Beaker Plating 2 x 8mm/4 x 6mm

Anode Bag x 2/4

Cleaner – 500ml

Stainless mesh electrode – 500ml

Stirring Bar – Medium

Plating Beaker – 500ml

Beaker Lid – 500ml x 2

Rinse beakers x 2 – 500ml

These same core products can be scaled down further to 250ml or up to 2 litres.

The rest of the items on the kit list can stay.