Our Rose Gold Tank Plating Solution is designed for use with the Spa Plating tank plating process. To run the process, Rose Gold Replenisher A and B will need to be added. To find out how to use the replenishers, please see our Rose Gold Tank Plating Calculator by clicking on the tab called ‘Calculator’ above.

Please note that this solution plates decorative layers up to 0.3 micron.

Please note: The solution should only be agitated lightly to ensure an even temperature distribution. Turn off the agitation when plating.

HS Code: 3824 99 70

Our Rose Gold Tank Plating Kit and a fresh bath of our Rose Gold Tank Plating Solution will plate an 18 karat layer of rose gold plate. This guide takes you through the steps of using this kit by showing you how to prepare a test strip as a sample, or swatch of our 18 karat Rose Gold Tank Plating Solution. Once this is done, you will have established a standard shade of 18 karat rose gold that you can refer back to.

It is vital to do test strip because, as you plate your items, you will deplete your rose gold plating solution and will need to add more of our Rose Gold Tank Replenisher A and B to maintain this 18 karat shade of rose gold. By comparing your plated pieces to the initial test strip, you will be able to judge when the bath needs to be topped up with the replenishers.

This isn't the only way of telling if the rose gold bath needs replenishing, as using our Rose Gold Tank Plating Calculator will also indicate what needs to be added to maintain an 18 karat shade as you plate your items.

Of course, once you have plated a number of items and become used to adding the replenisher A and B to maintain this shade of 18 karat rose gold, you can then experiment with achieving different shades of rose gold. Adding Replenisher A to an 18 karat bath increases the paleness of the deposit by increasing the amount of gold in the deposit. Conversely, adding Replenisher B to an 18 karat bath increases the redness of the deposit by increasing the amount of copper in the deposit.

Please note: The Rectifier shown in this project has now been discontinued and replaced by the MF Rectifier Mk II.

Working out the settings for your Rose Gold Tank Plating Kit with our Rose Gold Tank Plating Calculator and instructions on maintaining the 18kt shade of rose gold of your plating bath

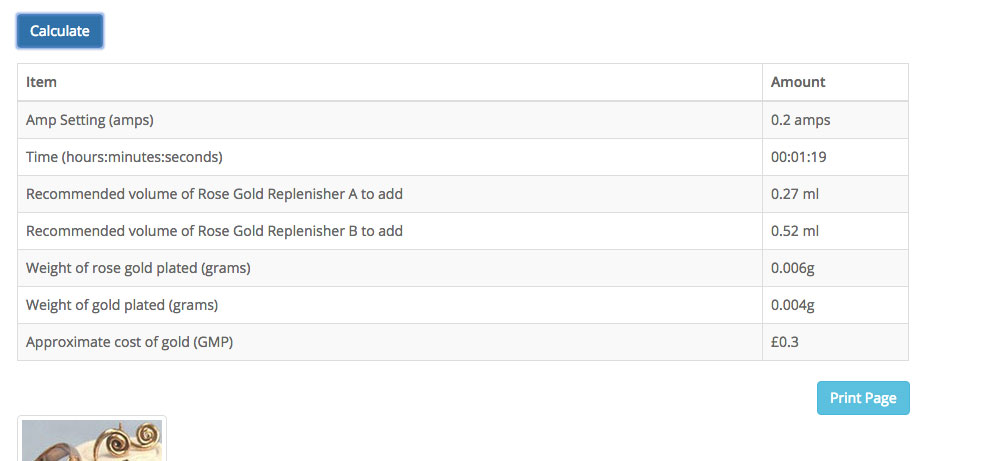

Before you start setting up your kit you will need to use our Rose Gold Tank Plating Calculator to work out plating times and settings for the Tank Plating Rectifier. All of our Palladium Plated Test Strips are a standard surface area of 20 squared centimetres up to the scored line. Open the Rose Gold Tank Plating Calculator and enter in 0.20 where it asks for the thickness in microns. Then for surface area put in 20 and volume of solution purchased, 1000ml. Press the ‘Calculate’ button and make a note of the settings. These are the settings that you will use to set up your MF Rectifier and to time the plating process. It will tell you how much of the Replenisher A and B you will need to add after you have plated, to return the bath to an 18 karat rose gold.

Clearly, it is impossible to measure out the very small amounts of replenisher that the calculator returns on one plate. What you will need to do is to keep a note of the suggested amounts of Replenisher A and B after each plate and when it has reached a measurable amount, add this to the bath.

1. Setting up your rose gold tank plating equipment

Below is a video showing you how to set up your tank plating equipment.Please remember to set the Tank Plating Rectifier to the setting recommended on our Rose Gold Tank Plating Calculator and the Economy Rectifier, which is used to power the Cleaner bath, should be adjusted to 3 volts.

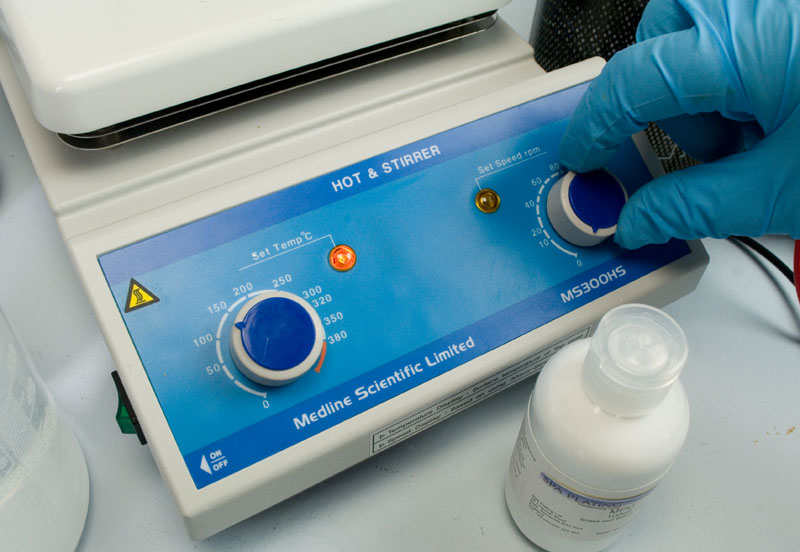

2. Bringing the Rose Gold Plating Solution up to temperature

For the purposes of making a test strip we recommend the operating temperature of your rose gold solution should be 60 degrees centigrade. While the solution is coming up to temperature the stirring mechanism of the Hot Plate Stirrer will need to be turned on. Place the Mini Stirring Bar in the rose gold beaker so that the solution is agitated throughout the heating process, to ensure even heat distribution. Monitor the temperature of your solution with your Temperature Gauge.

3. Turning off the Stirrer

Once the solution is up to temperature, turn off the Stirrer.

4. Peeling off the plastic

To plate the test strip you’ll first need to peel off the clear strip of blue plastic. You will now clearly see the scored line that you’ll immerse the strip up to in the plating bath.

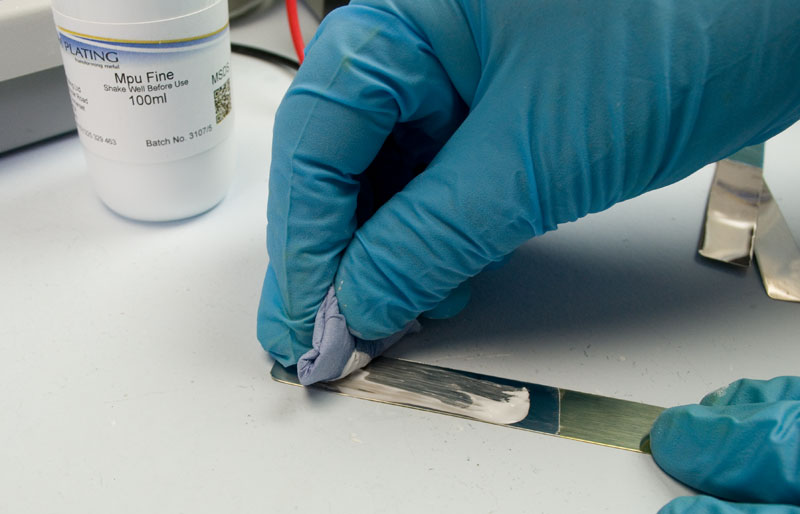

5. Cleaning the test strip with MPU Fine

Clean the palladium plated surface with a small amount of our MPU Fine.

6. Electrocleaning the test strip

To ensure you have a completely water break free surface, place the test strip in the bath of Cleaner. Leave it in the Cleaner for about a minute.

7. Rinsing the test strip

Once the test strip has been cleaned, rinse off the Cleaner by using our Rinse Bottle over the bath of Cleaner. This will contain traces of Cleaner in the Cleaner bath and stop cross contamination of your rose gold solution. Pass the test strip through the two rinse baths.

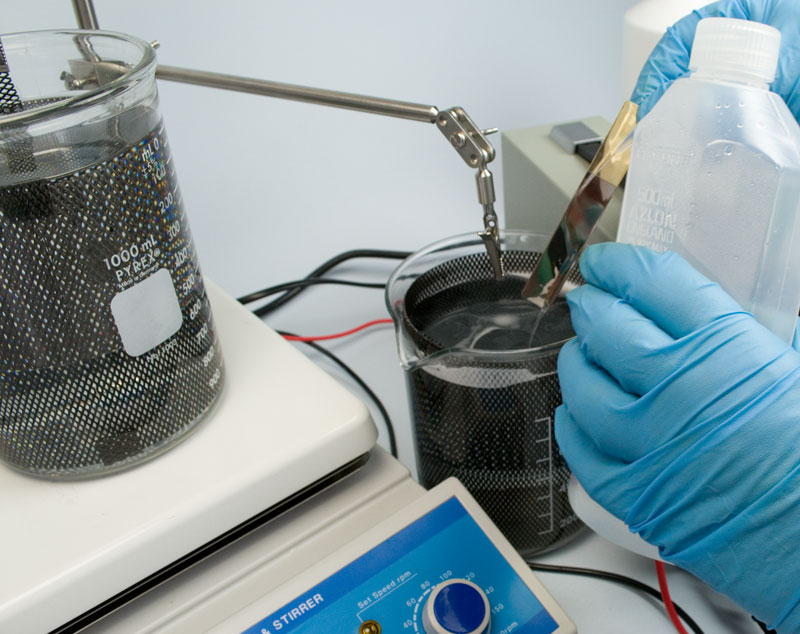

8. Plating the test strip in the Rose Gold Plating Solution

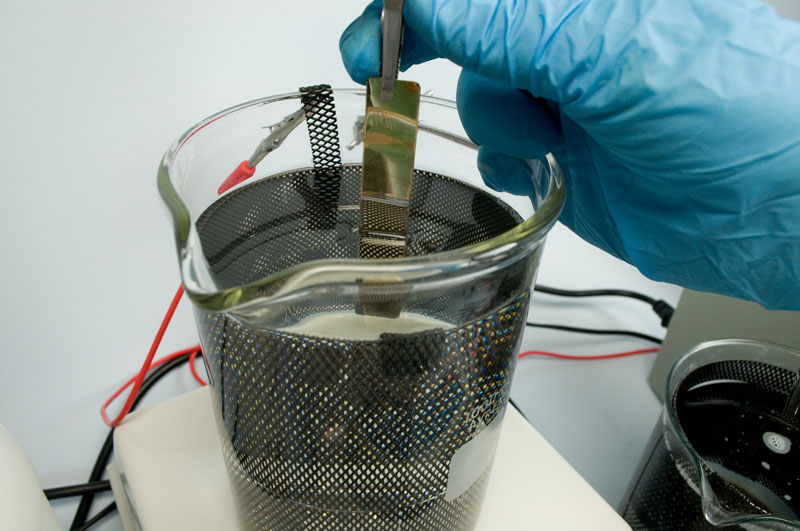

Position the test strip in the rose gold bath so that the strip is submerged up to the scored line. Switch on the Tank Plating Rectifier to start the plating.

9. Turning on the Tank Plating Rectifier

Switch on the MF Rectifier Mk II to start the rose gold plating.

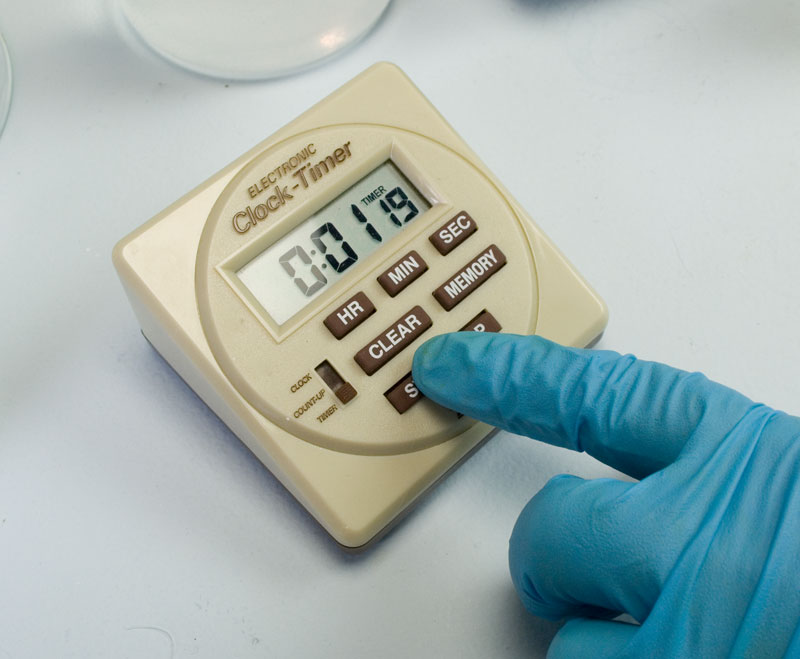

9. Setting the time

Start the Plating Timer.

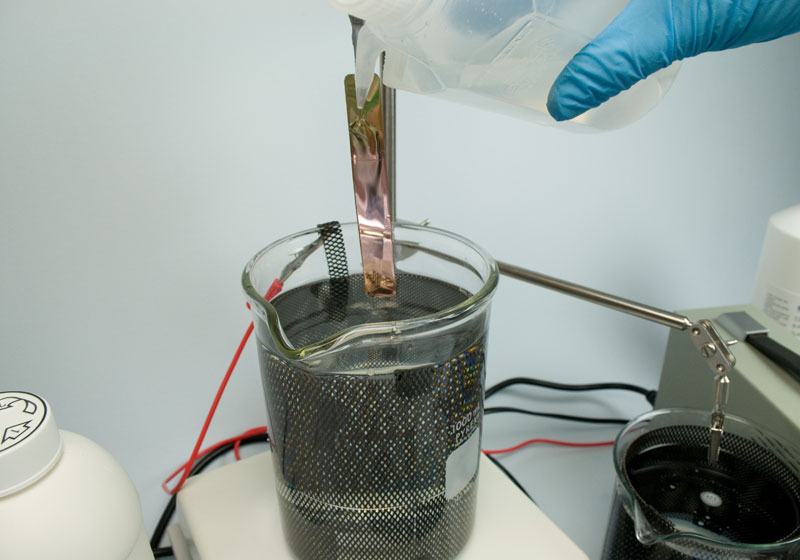

10. Rinsing the test strip

Once the plating time is up, switch off the rectifier and remove the test strip from the crocodile clips. Again, use the Rinse Bottle to rinse off any solution back into the plating beaker to contain as much as the contents of the bath in the plating beaker as possible.

11. Final rinse

Pass the test strip through the final rinse bath.

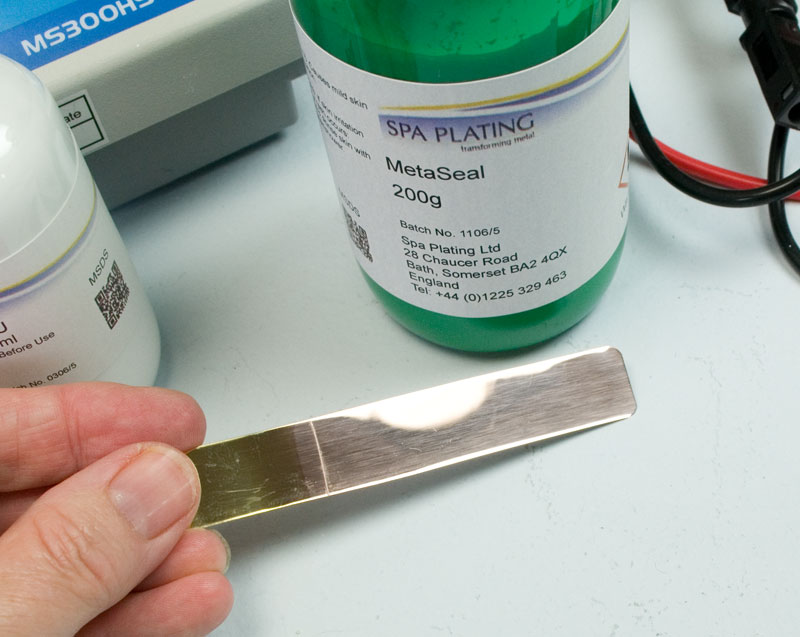

12. Final finishing

Finish your 18kt rose gold test strip with MetaSeal.

This test strip now provides a record of how the plate looks for 18kt rose gold and will provide an essential reference point for subsequent plating results.

Rose Gold Tank Plating Calculator

How to use this calculator :

1. In the first box, enter the thickness that you want to plate to in microns (thousandths of a millimetre).

2. In the second box, enter the surface area of the article in square centimetres (cm2).

3. Click the ‘Calculate’ button.

4. Read off the amp setting for your rectifier, the plating time and the volume of replenishers A and B to add before starting the plating sequence.

5. The weight of rose gold and gold plated together with the approximate job cost are included in the final three boxes.

Operating Conditions and Deposit Data

| Plating Factor (PF) |

0.005 A/cm2 (see notes below) |

| Plating rate |

~0.14 micron per minute at 0.01A/cm2 |

| Temperature |

50 – 65 °C (60°C optimum) |

| pH |

9.2 – 9.8 |

| Gold concentration |

2 grams per litre |

| Agitation |

None |

| Electrode |

Mesh |

| Colour designation |

5N |

| Gold content in plate |

75% at 60°C (see notes below on variation with temperature) |

| Copper content in plate |

25% at 60°C (see notes below on variation with temperature) |

| Cathode efficiency |

~25% at Plating Factor = 0.01A/cm2 |

| Hardness |

380 – 390 Hv |

| Density of deposit |

14.4 g/cm3 |

| Stress |

4.4 kg/mm2 |

| Special storage requirements |

None |

| Shelf life |

1 – 2 years |

| Health and Safety classification |

Harmful |

| Special considerations |

Contains potassium cyanide (0.35%) |

| Transport (UN number) |

None: Not classified as dangerous for transport |

Notes:

- Recommended plating thickness between 0.2 and 0.3 (bright coatings up to 1 micron have been obtained).

- We recommend that the part is immersed as quickly as possible in the plating solution with the power on.

leaving the part in the plating solution without power on results in hazy deposits.

- Temperature: Increasing from 50° to 65°C decreases the percentage of gold by

approximately 5%.

- Increasing the temperature from 50°C to 60°C almost doubles the plating rate

- Reducing the plating factor (PF) from 0.01 to 0.005 has very little effect on composition

but reduces the plating rate by almost half.

- Adjusting the pH within the range 10.5 – 11.5 has little effect on the composition or

plating rate.

- Plating will start to loose brightness at around 0.2 – 0.3 micron. We recommend light polishing to bring up the full

lustre on deposits up to 1 micron in thickness or more heavy polishing/burnishing on deposits greater

than 1 micron. Barrel burnishing with stainless steel shot is especially effective on rose gold vermeil coatings

(over 3.25 microns).

- The plating calculator for this solution is an excellent way of estimating the initial maintenance

additions; however, it becomes less effective as the bath ages and we recommend that

the user makes adjustments based on their own standards.

- We recommend storing solution in a bottle if solution is going to be stored for a prolonged period of time.

Recommendations for adjusting the composition (changing the colour) of the deposit by adding replenishers.

- Adding Replenisher A to a new bath increases the paleness of the deposit by increasing the amount of gold

in the deposit. On a fresh bath, Adding 12.5 ml of Replenisher A to 1 litre of new solution will increase the amount of

gold by approximately 2.5%.

- Adding Replenisher B to a new bath increases the redness of the deposit by increasing the amount of

copper in the deposit.

General guide;

Certain small items, for example Swabs, Nibs and Plating Pens can be sent by normal post within the UK

- The courier option for UK deliveries is FedEx

- Free UK mainland delivery available on orders over £200

- International orders usually 3-5 working days.

For all price quotations for deliveries, please add your items to our shopping cart. You will be able to see the shipping costs by clicking on the ‘Calculate shipping’ button in the cart and before checking out.

Please click on the link below to download the SDS for this product:

https://goldn.b-cdn.net/msds/rose_gold_tank_plating_solution.pdf

Q:

Hello there,

I am very interesting in purchasing your rose gold tank kit but wish to know whether I can plate jewellery which is Sterling silver but has already been rhodium plated? Basically I want to go over the top of it with a rose gold plate.

Is this possible please?

A:

Thank you for your enquiry.

I’ve just plated some rhodium plating rings with rose gold and the adhesion is perfect.

Our rose gold can be plated to 0.25 micron without the need for polishing/burnishing. Deposits over this

will require increasing polishing/burnishing as the thickness increases.

We have found that for rose gold vermeil work (3.25 microns and over) one hour in a barrel burnisher with

mixed stainless steel shot is perfect for brining up the full lustre of the coating.

Kind regards

Richard Palmer BSc(Chem.) MRSC

Director